Thermocyclic control

Basic idea

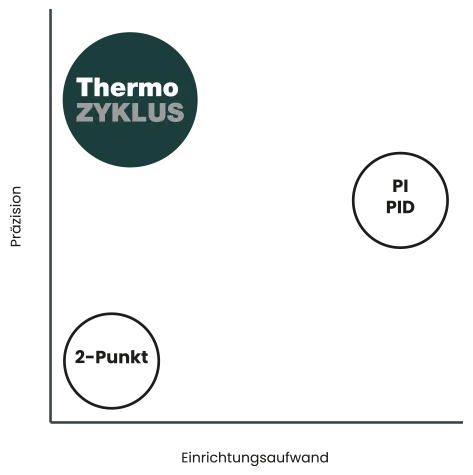

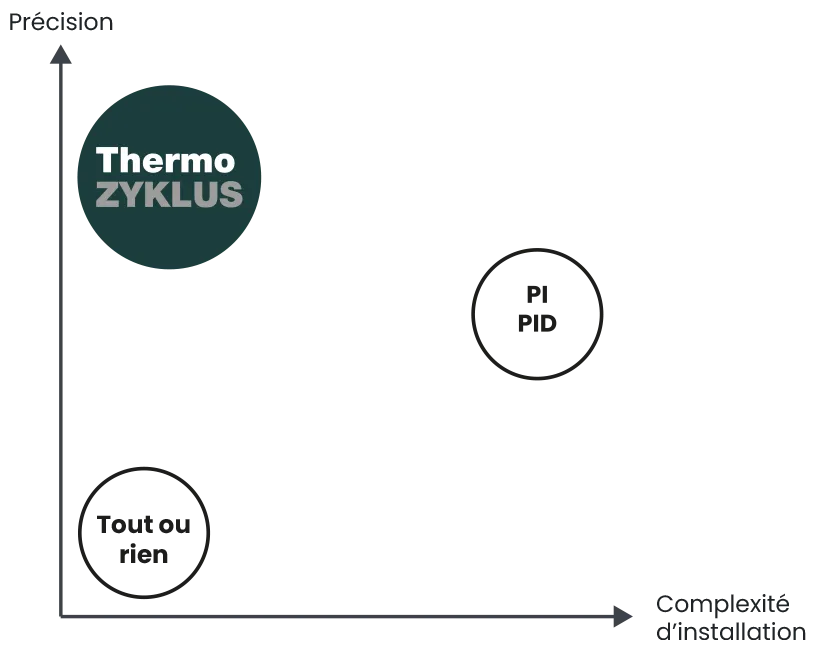

You can regulate the temperature in a room with a thermostat (2-point), and simply not care about the resulting temperature oscillations. The result is usually disastrous.

It is also possible to control a room with a PI or PID controller with the aim of making the temperature oscillations disappear. Then you have to determine 2 or 3 specific parameters for each room individually, which requires a lot of effort and is therefore almost never feasible. Without this effort, the result is not much better. Moreover, the parameters become wrong as soon as something changes in the room or its environment. And in case of large dead times (i.e. surface heating) these controllers do not work at all.

However, the room can also be regarded as a heat oscillator and the temperature oscillations can be controlled down to very small values. This is the approach of thermocyclic control.

If you periodically apply a certain amount of heat to a room, the temperature will oscillate with a certain amplitude, frequency and phase. These 3 values will differ from room to room. So in them is the heat characteristic of that particular room. So with a suitable excitation, the room itself provides the parameters needed to control the temperature. If something changes in the room or its environment, these values will automatically change as well.

Precise measurement of the temperature oscillation then provides the prerequisite for controlling the amplitude of the oscillation down to a small value that can no longer be felt. However, this micro-vibration still provides enough information to compensate for any change in the room or its environment.

Régulation thermocyclique

In a completely different approach, one can consider the product as an oscillator of heat and try to reduce the variations to extremely low values in order to be able to control them rather than reduce them. This is the basis of thermocyclic regulation. The regulation of the chauffage becomes algorithmic and the IA constantly adapts to its environment. The precision is significantly higher, as are the comfort and economy.

Constant room temperature

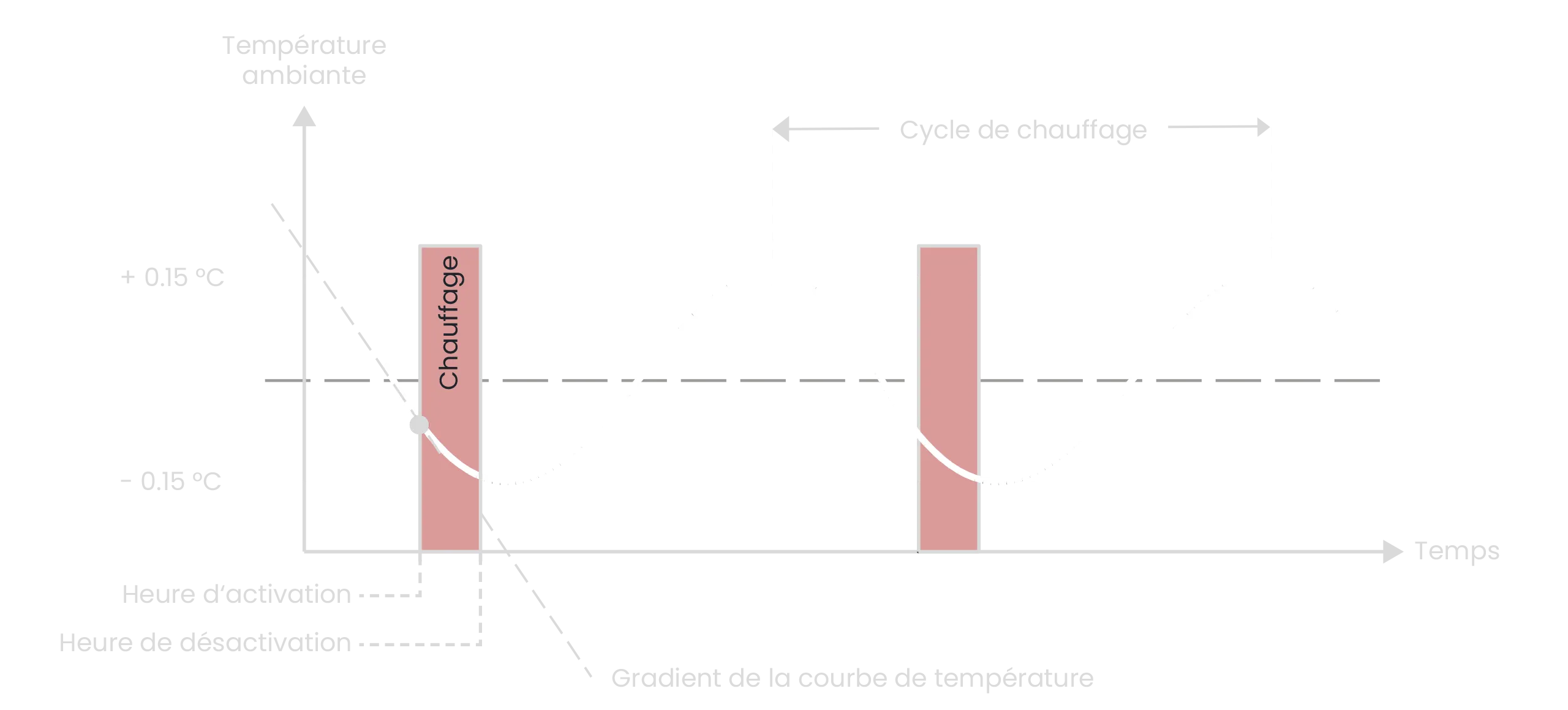

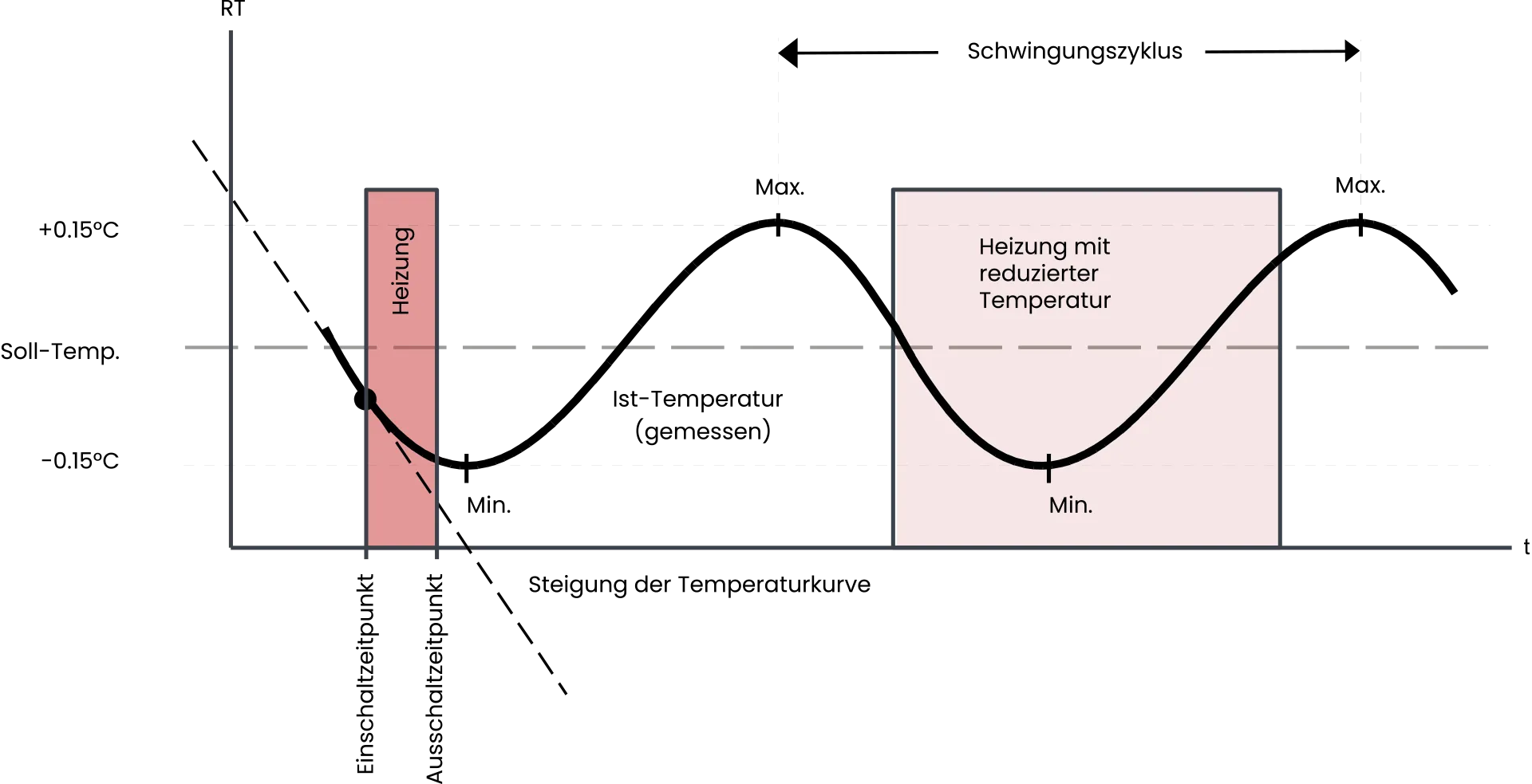

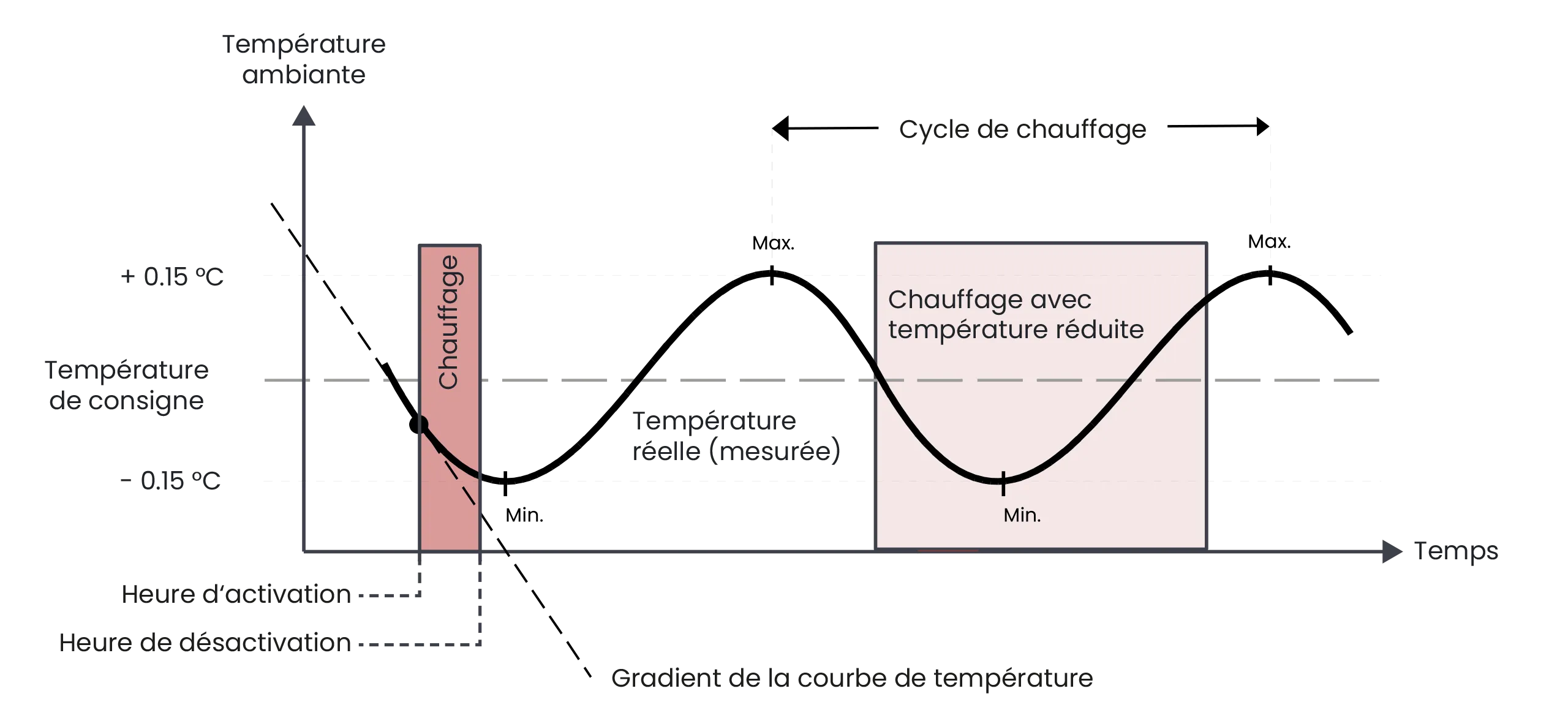

Turning the heater on and off creates a very small controlled temperature oscillation around a set point temperature.

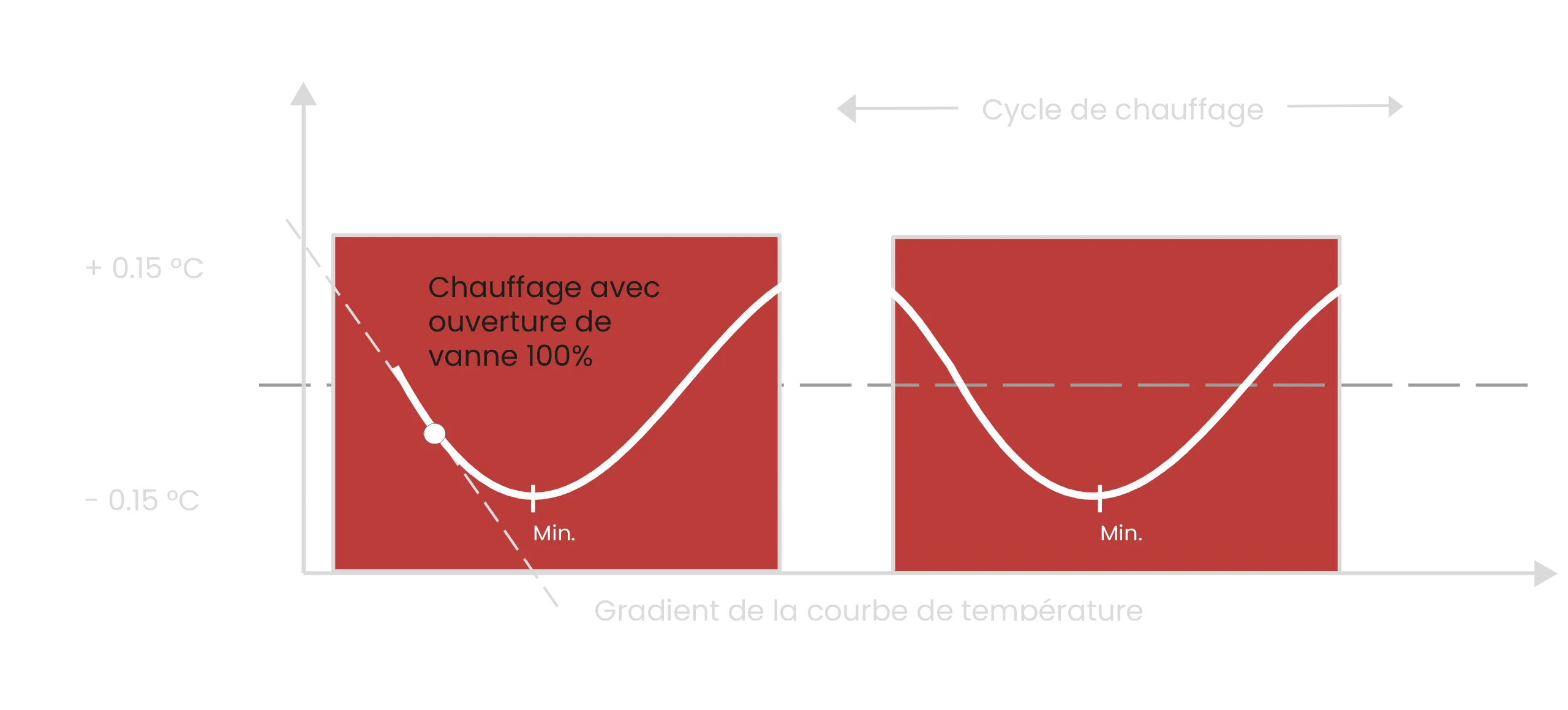

The minimum and maximum of this oscillation depend on the times at which the heating is switched on and off. These times can be determined from the temperature curve. The following relationships apply:

The temperature minimum of the oscillation depends on the measured actual temperature and the slope of the temperature curve at the switch-on time.

If you look closely at the graph, you can intuitively see that the above relationships are correct. If, for example, the heating is switched on later or the slope is steeper, the minimum will be lower. If the heating is switched on longer, the maximum will shift upwards. Mathematically put into a suitable form, this results in a system of equations with some parameters. The solution of this equation system provides the correct switch-on and switch-off times for certain minima and maxima, e.g. for +/- 0.15°C below or above the set temperature.

The control starts with parameters based on general empirical values. If the minima or maxima are then not as expected at +/- 0.15°C, the parameters of the equation system are adjusted accordingly. This correction is not only made at the beginning, but after each oscillation cycle, so that the control constantly adjusts itself even if conditions change. This is where the 'thermocyclic' control gets its name from.

(European Patent No. 0 935 181, United States Patent No. US 65 22 954)

Température ambiante constante

The chauffage that is switched on or off generates a slight variation in controlled temperature and a temperature de consigne. The minimum and maximum values of this oscillation depend on the moments at which the chauffage is switched on or off. These moments are determined by the temperature curve. The following relationships are established: the minimum temperature of the oscillation depends on the actual temperature of the item and the temperature of the temperature curve at the moment of switching on.

This provides a mathematical system with certain parameters. The solution of the system is provided by the moments when the chauffage is switched on or off for certain minimum and maximum values, for example +/- 0.15°C compared to the temperature of consumption. The regulation is based on the parameters that are the values of experience. If the minimum and maximum are not as expected at + /- 0.15°C, the parameters of the mathematical system are adapted accordingly based on the IA. This correction is not only made at the start of the installation, but rather after each chauffeur cycle, which allows the regulation to adapt to every change in the product in real time. This is where "thermocyclic" regulation gets its name.

(Brevet européen No. 0 935 181, United States Patent No. US 6522 954)

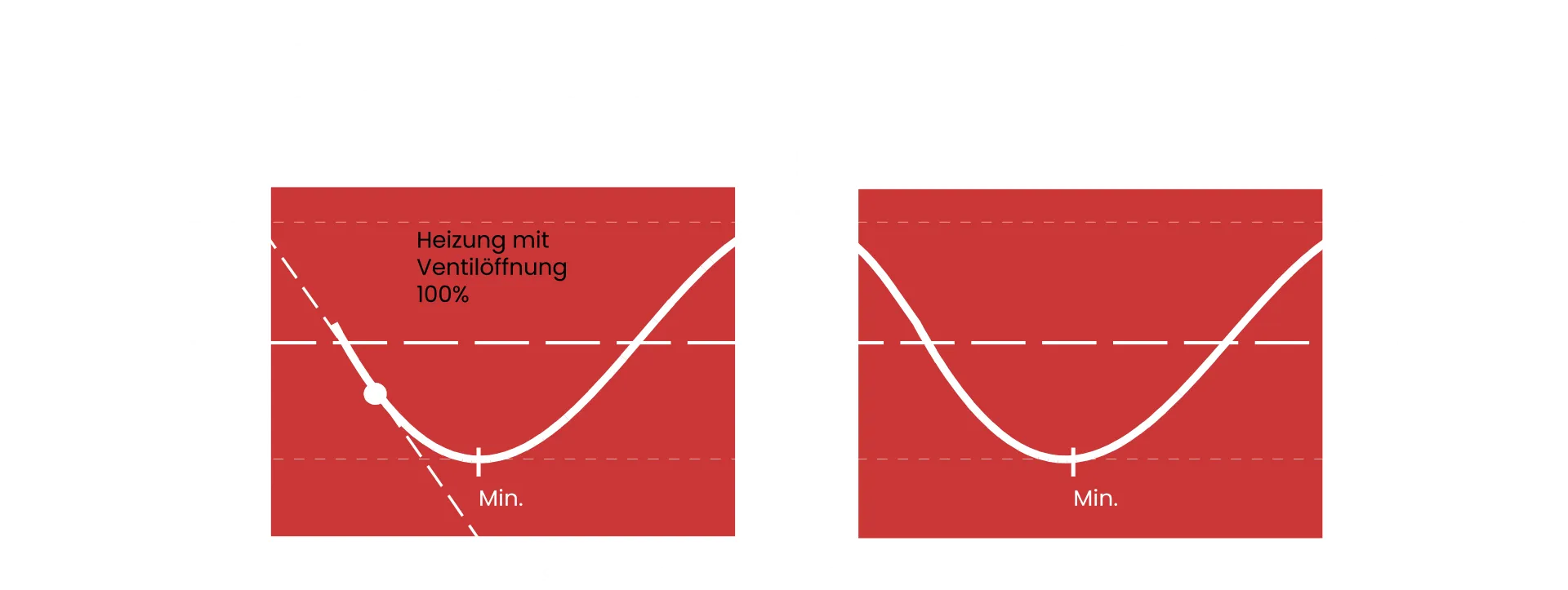

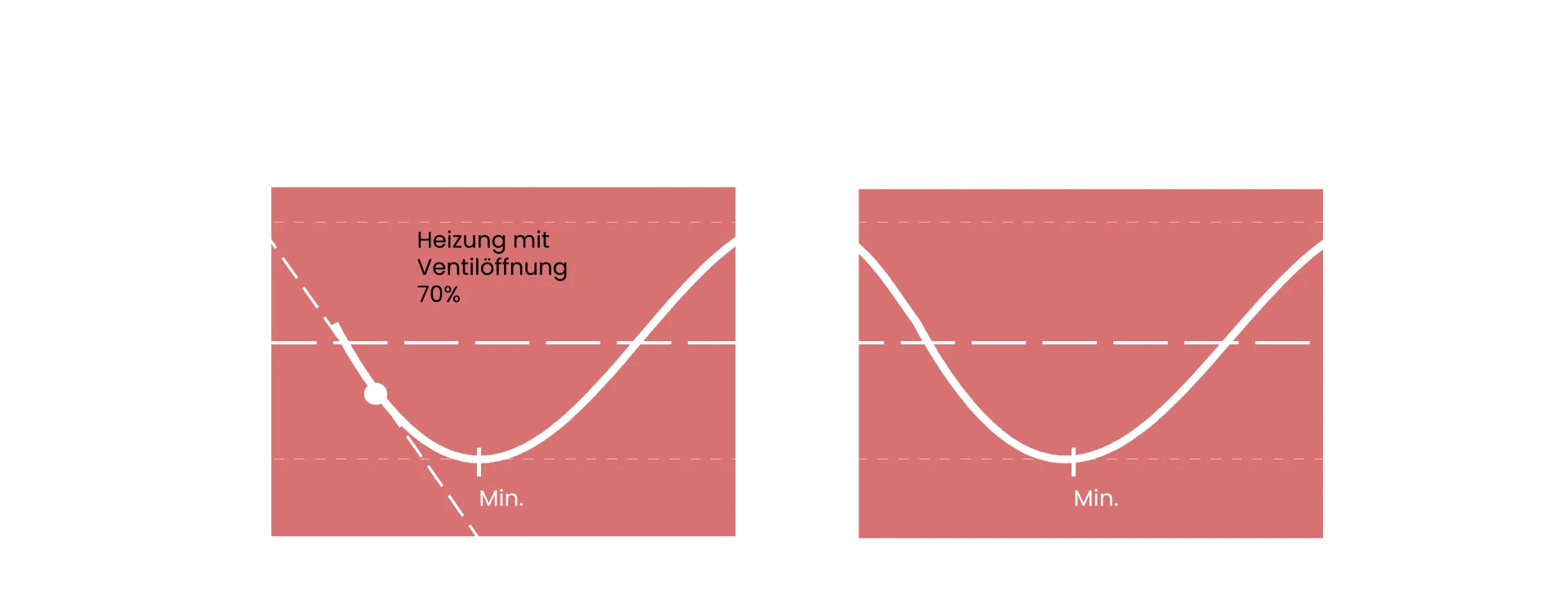

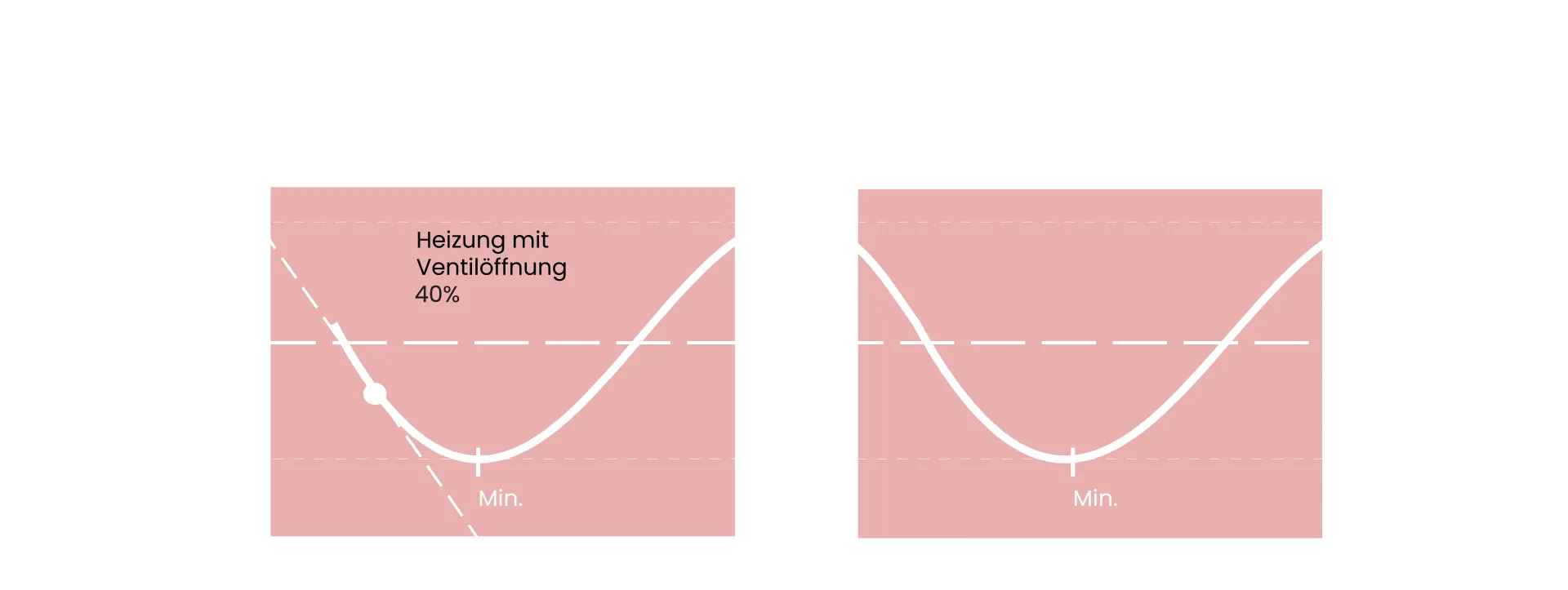

Flow temperature

As can be seen from the previous diagram, heating is only carried out there for a very short time as an example, but obviously at a sufficiently high temperature so that the required energy can also be delivered in this short time. The ratio of the heating time to the time during which no heating takes place (heating pause) is therefore very small.

With a lower temperature, the heating duration would increase accordingly. The ratio of the heating duration to the heating pause would then be very large.

The ratio of the heating duration to the heating pause thus indicates whether the flow temperature can be lowered or raised.

(European Patent No. 0 935 181, United States Patent No. US 65,22,954)

Température de départ

As can be seen from the graph above, the period of heating is long but manifests itself at a temperature that is too high for the necessary energy to be supplied in such a short period of time. The ratio between the duration of heating and the duration of absence of heating is therefore very small.

With a lower temperature, the duration of chauffeuring would increase proportionally. The ratio between the duration of chauffeuring and the duration of the absence of chauffeuring would then be very high.

Le rapport entre la durée de chauffe et la durée d'absence de chauffe indique ainsi si on peut augmenter ou réduire la température de départ.

In mathematical terms, the minimum value of the temperature at departure can be defined. For this purpose, the regulation must reduce the temperature as far as necessary until at least one part reaches a ratio at which the oscillations do not decay. The adaptation takes place after each cycle, the regulation is dynamic and adapts permanently.

(Brevet européen No. 0 935 181, United States Patent No. US 65,22,954)

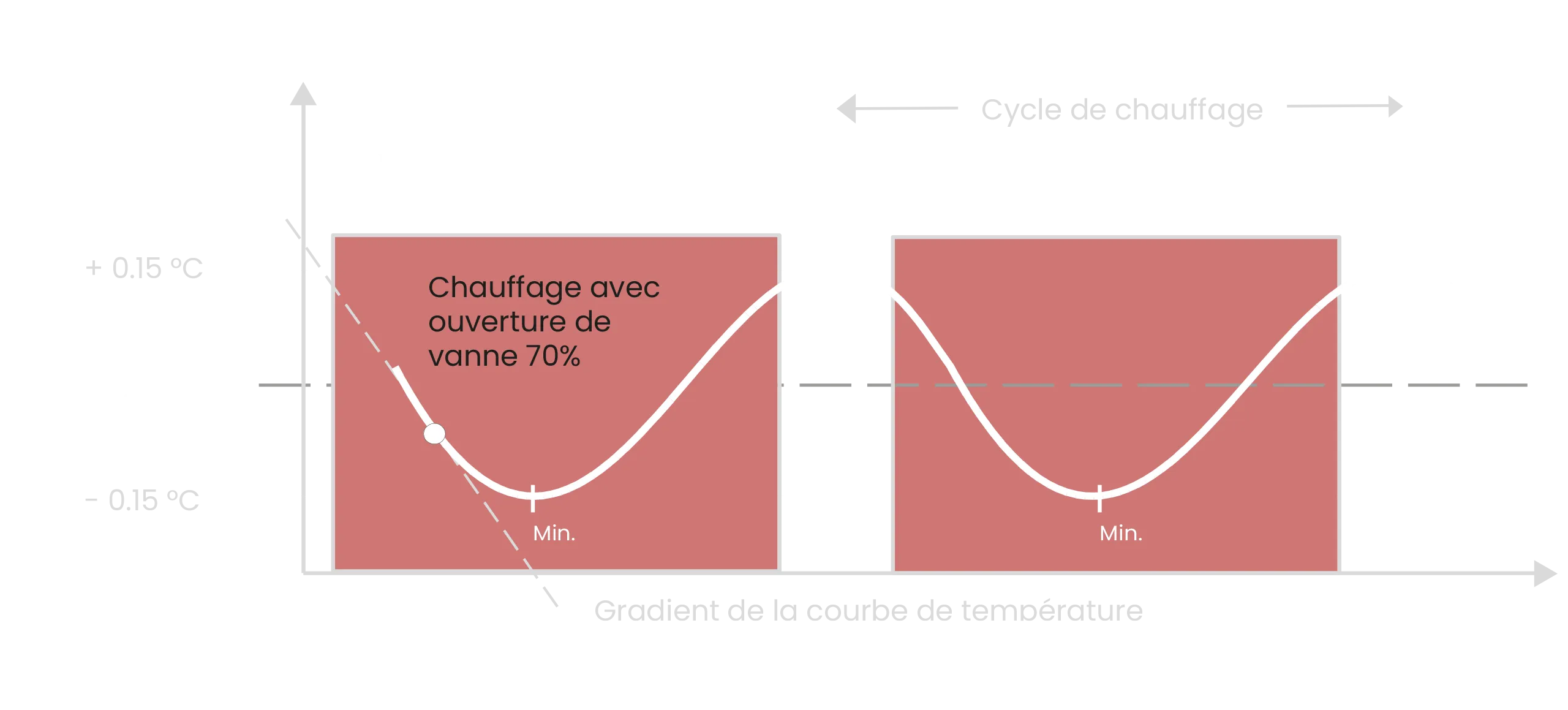

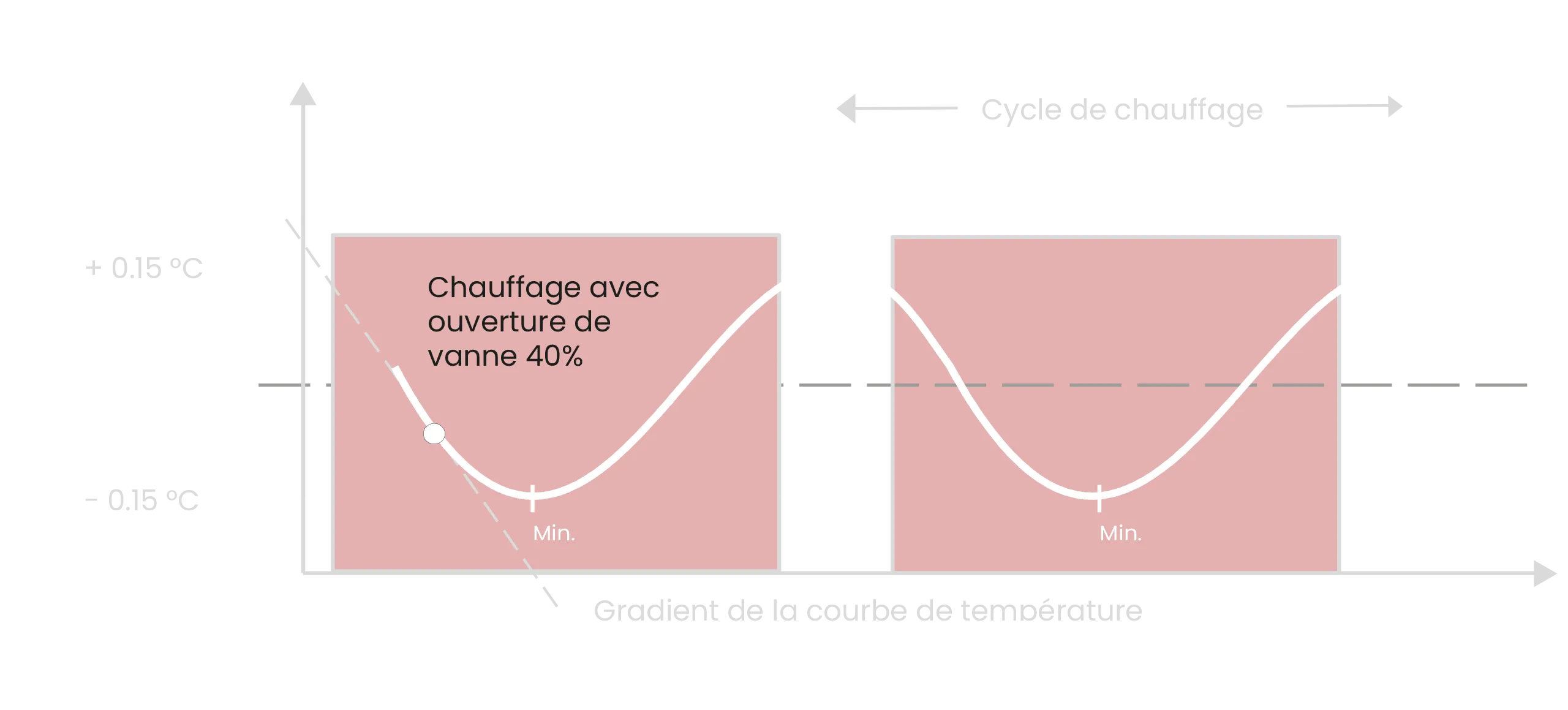

Hydraulic balancing

The ratio of heating duration to heating pause can also be used for automatic hydraulic balancing. To do this, the control system first limits the valve opening in each room to such an extent that the oscillations do not yet stop.

Then the flow temperature is adjusted so that the valve opening is 100% in at least one room. These

adjustments are also made after each cycle, so that the control also adjusts itself continuously here.

(European Patent No. 2 354 682, United States Patent No. US 9,046,274)

Équilibrage hydraulique

With thermocyclic regulation, the relationship between the duration of heating and the duration of the absence of heating is used to achieve automatic balancing of the installation. For this purpose, the system first limits the opening of the tank in each item so that the oscillations do not occur. Then, the temperature of departure is adjusted in order to keep the opening of the vane at 100% in a single panel. These adjustments are also made after each chauffeur cycle.

(Brevet européen No. 2 354 682, United States Patent No. US 9,046,274)